Experience is over the world visit

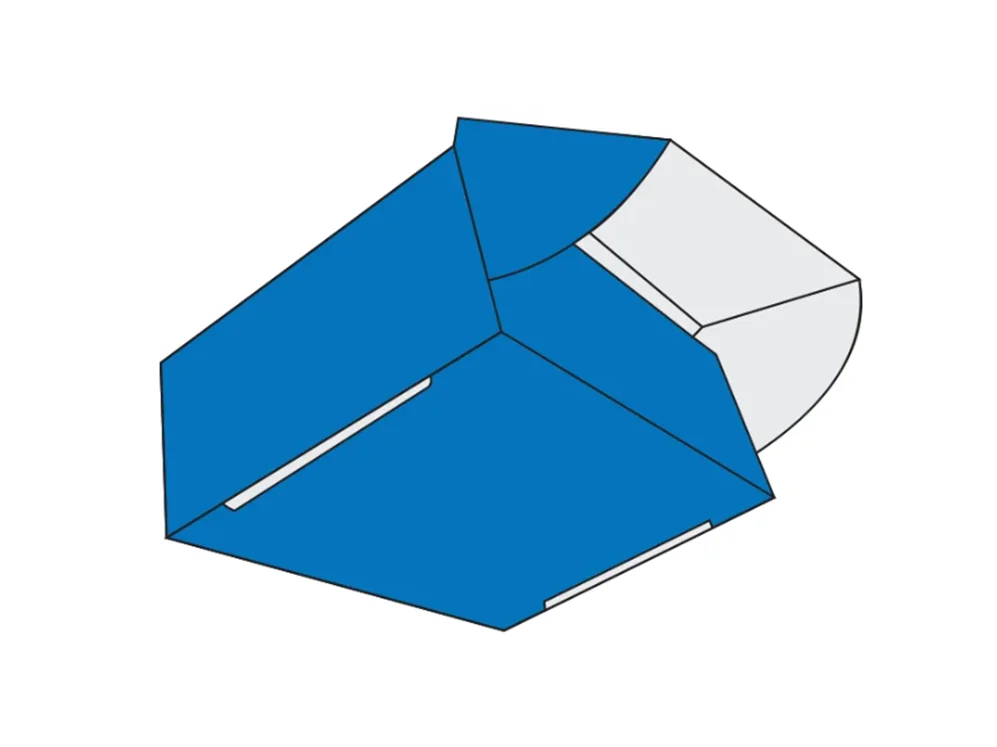

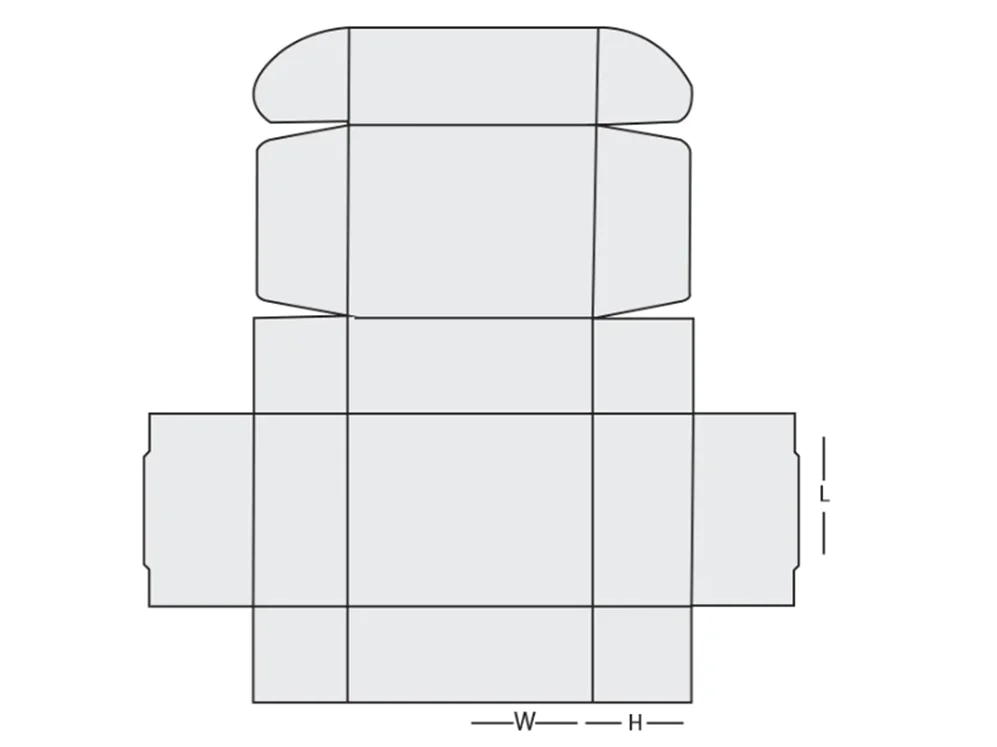

We offer you the freedom to tell your brand story through stunning packaging prints. To create your ideal packaging, it’s essential that you specify your preferences. It’s a collaborative process: select box dimensions, choose the material, and upload images of your favorite packaging designs. In return, we'll bring your vision to life. Fill in your specifications and take a step toward elevating your business!

| Dimensions | Custom Shapes & Sizes |

| Printing | CMYK, PMS, No Printing |

| Material | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 - 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Finishing | Embossing, Debossing, Foil Stamping, Spot UV |

| Included Options | Die Cutting, Gluing, Scoring, Perforation |

| Proof | Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time | 8 - 10 Business Days, Rush Available |